PU-Timing-Belt-HTD-STD-3M-5M-8M-S2M-S3M-S4.5-S5M-S8M-T2.5-T5-T10-AT3-AT5-AT10-MXL-L-H-XL...

PU-Timing-Belt-HTD-STD-3M-5M-8M-S2M-S3M-S4.5-S5M-S8M-T2.5-T5-T10-AT3-AT5-AT10-MXL-L-H-XL.

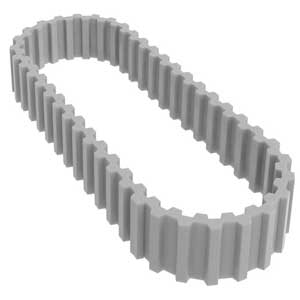

Double Sided PU-Timing-Belt-DHTD-DSTD-T5-DL T10-DL AT5-DL AT10-DL T20-DL AT20-DL DT5 DT10 DT20 DAT5 DAT10 DAT20

T-Series

| Trapezoidal Profile | T2.5 | T5 | T10 | T20 |

| Tooth Pitch t [mm] | 2.5 | 5 | 10 | 20 |

| Tooth Angle 2β [°] | 40 | 40 | 40 | 40 |

| Tooth Height h [mm] | 0.7 | 1.2 | 2.5 | 5 |

| Overall Belt Thickness H [mm] | 1.3 | 2.2 | 4.5 | 8 |

| Unit Mass kg/m (Width: 10mm) | 0.012 | 0.020 | 0.042 | 0.075 |

AT-Series

| AT Profile | AT3 | AT5 | AT10 | AT20 |

| Tooth Pitch t [mm] | 3 | 5 | 10 | 20 |

| Tooth Angle 2β [°] | 50 | 50 | 50 | 50 |

| Tooth Height h [mm] | 1.1 | 1.2 | 2.5 | 5 |

| Overall Belt Thickness H [mm] | 1.9 | 2.7 | 5 | 8 |

| Unit Mass kg/m (Width: 10mm) | 0.022 | 0.033 | 0.058 | 0.096 |

Double Sided-Series

| Double Sided Profile | T5-DL | T10-DL | T20-DL | AT5-DL | AT10-DL | AT20-DL |

| Tooth Pitch t [mm] | 5 | 10 | 20 | 5 | 10 | 20 |

| Tooth Angle 2β [°] | 40 | 40 | 40 | 50 | 50 | 50 |

| Tooth Height h [mm] | 1.2 | 2.5 | 5 | 1.2 | 2.5 | 5 |

| Overall Belt Thickness H [mm] | 3.4 | 7 | 13 | 3.9 | 7 | 13 |

| Unit Mass kg/m (Width: 10mm) | 0.028 | 0.059 | 0.1 | 0.043 | 0.078 | 0.127 |

Self Tracking-Series

| Self Tracking Guide Profile | HK13 | T5K6 | T10K6 | T10K13 | T20K13 | AT5K6 | AT10K13 | AT20K13 |

| Tooth Pitch t [mm] | 12.7 | 5 | 10 | 10 | 20 | 5 | 10 | 20 |

| Belt Thickness H1 [mm] | 2 | 2.5 | 4.5 | 4.5 | 8 | 4.5 | 4.5 | 8 |

| Tooth Height h [mm] | 2.3 | 1.2 | 2.5 | 2.5 | 5 | 1.2 | 2.5 | 5 |

| Guide Width B [mm] | 13 | 6 | 6 | 13 | 13 | 6 | 13 | 13 |

| Overall Belt Thickness with Guide H2 [mm] | 8.3 | 5 | 5.3 | 8.5 | 8.5 | 5.5 | 8.5 | 9.4 |

Imperial-Series

| Imperial Profile | MXL | XL | L | H | XH | XXH |

| Tooth Pitch t [mm] | 2.032 | 5.080 | 9.525 | 12.700 | 22.225 | 31.750 |

| Tooth Pitch t [inches] | 0.080 or 2/25 | 0.200 or 1/5 | 0.375 or 3/8 | 0.500 or 1/2 | 0.875 or 7/8 | 1.250 or 11/4 |

| Tooth Angle 2β [°] | 40 | 50 | 40 | 40 | 40 | 40 |

| Tooth Width Lr [mm] | 1.14 | 2.57 | 4.65 | 6.12 | 12.57 | 19.05 |

| Tooth Height h [mm] | 0.51 | 1.27 | 1.91 | 2.29 | 6.35 | 9.53 |

| Overall Belt Thickness H [mm] | 1.2 | 2.3 | 3.5 | 4.3 | 11.2 | 15.7 |

| Foot Radius Rr [mm] | 0.13 | 0.38 | 0.51 | 1.02 | 1.57 | 2.29 |

| Head Radius Ra [mm] | 0.13 | 0.38 | 0.51 | 1.02 | 1.19 | 1.52 |

| Unit Mass kg/m (Width: 10mm) | 0.012 | 0.021 | 0.035 | 0.041 | 0.110 | 0.147 |

HTD-Series

| HTD Profile | 2M | 3M | 5M | 8M | 14M | 20M |

| Tooth Pitch t [mm] | 2 | 3 | 5 | 8 | 14 | 20 |

| Tooth Height h [mm] | 0.7 | 1.2 | 2.06 | 3.36 | 6 | 8.4 |

| Overall Belt Thickness H [mm] | 1.3 | 2.4 | 3.8 | 6 | 10 | 13.2 |

| Unit Mass kg/m (Width: 10mm) | 0.013 | 0.024 | 0.035 | 0.058 | 0.1 | 0.132 |

STD-Series

| STPD/STS Profile | S2M | S3M | S4.5M | S5M | S8M | S14M |

| Tooth Pitch t [mm] | 2 | 3 | 4.5 | 5 | 8 | 14 |

| Tooth Height h [mm] | 0.76 | 1.14 | 1.71 | 1.91 | 3.05 | 5.3 |

| Overall Belt Thickness H [mm] | 1.36 | 1.9 | 2.81 | 3.4 | 5.3 | 10.2 |

| Unit Mass kg/m (Width: 10mm) | 0.013 | 0.019 | 0.0285 | 0.034 | 0.052 | 0.1 |

RPP-Series

| RPP & Flat Belt Profile | P3M | P5M | P8M | P14M | P1 | P2 | P3 | P4 |

| Tooth Pitch t [mm] | 3 | 5 | 8 | 14 | – | – | – | – |

| Tooth Height h [mm] | 1.15 | 1.95 | 3.2 | 6 | – | – | – | – |

| Overall Belt Thickness H [mm] | 1.9 | 3.5 | 5.4 | 10 | 1 | 2 | 3 | 4 |

| Unit Mass kg/m [Width: 10mm] | 0.024 | 0.035 | 0.058 | 0.1 | 0.02 | 0.049 | 0.071 | 0.089 |

Helical Offset Tooth

| Eagle SilentSync QST Profile | Eagle 5M | Eagle 8M | Eagle 14M |

| Tooth Pitch t [mm] | 5 | 8 | 14 |

| Tooth Height h [mm] | 1.9 | 3.05 | 5.3 |

| Overall Belt Thickness H [mm] | 3.6 | 5.33 | 8.64 |

| Unit Mass kg/m (Width: 10mm) | 0.05 | 0.06 | 0.115 |

V-Series

| Twist Link Profile | Z-10 | A-13 | B-17 | 8 T | 10 T | 13 T | 17 T | 22 T |

| Weight [kg/m] | 0.12 | 0.168 | 0.2254 | 0.116 | 0.131 | 0.158 | 0.223 | 0.359 |

Modulus-Series

| Modulus Model | π | Pitch pb(mm) | Tooth Height ht(mm) | Belt Height hs(mm) | Angle 2В |

| 1 | 3.142 | 3.142 | 0.6 | 1.2 | 40 |

| 1.5 | 3.142 | 4.712 | 0.9 | 1.65 | 40 |

| 2 | 3.142 | 6.283 | 1.2 | 2.2 | 40 |

| 2.5 | 3.142 | 7.854 | 1.5 | 2.75 | 40 |

| 3 | 3.142 | 9.425 | 1.8 | 3.3 | 40 |

| 4 | 3.142 | 12.566 | 2.4 | 4.4 | 40 |

| 5 | 3.142 | 15.708 | 3 | 5.5 | 40 |

| 7 | 3.142 | 21.991 | 4.2 | 7.7 | 40 |

| 10 | 3.142 | 31.416 | 6 | 11 | 40 |